charpy impact tester for metals|what is charpy impact test : services For a comprehensive solution to test impact toughness in metals, our Charpy Impact Tester for Metals is designed to meet ASTM E23 standards, ensuring high-quality and reliable results. If your focus is on plastics or polymers, the . WEBIdle Farming Business. MarketJS 4.4 29,383 Votos. Idle Farming Business é um jogo inativo onde você assume o controle de um lindo terreno para construir sua própria .

{plog:ftitle_list}

The latest tweets from @Yayamineira

The ISO 148-1 standard specifies the Charpy (U-notch and V-notch) impact test on metals for determination of the impact strength. The impact strength of a material is an important characteristic for applications in pipeline construction .

This makes Charpy testing a popular choice for assessing the toughness of metals like steel, as well as polymers, composites, and ceramics. Here’s how the process works: The test .

Charpy impact testing determines the impact energy of materials. The test procedure, the application of charpy testing, factors affecting impact energy, the ductile to brittle transition are all covered. . Metals tend .

For a comprehensive solution to test impact toughness in metals, our Charpy Impact Tester for Metals is designed to meet ASTM E23 standards, ensuring high-quality and reliable results. If your focus is on plastics or polymers, the .

For a comprehensive solution to test impact toughness in metals, our Charpy Impact Tester for Metals is designed to meet ASTM E23 standards, ensuring high-quality and reliable results. If your focus is on plastics or polymers, the Charpy Izod Pendulum Impact Tester for Plastics is perfect for assessing the toughness of non-metal materials.

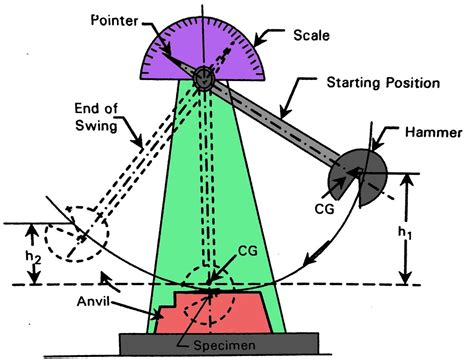

The Charpy impact test is performed to evaluate the resistance of the metal to breakage by flexural shock or impact load according to standard test method ASTM D6110. . that affect the yield behaviour and hence ductility of the material such as temperature and strain rate will affect the impact energy. 4. Fracture Mechanism. Metals tend to .The Class D Metals Impact Tester is a Single column impact testing system designed for Charpy Impact testing according to ASTM E23, ISO 148 and EN10045 industry standards. The Class D has has two popular models with peak capacities of 450J and 750J with optional pendulums for 150J, 300J, 450J and 600J. Charpy impact test standards. ASTM E23, ASTM D6110, ASTM A370, ASTM D256. ISO 13479, ISO 148-1. EN 10045-1, EN ISO 179-1 Izod impact testing. While Charpy impact testing is widespread for metals, Izod impact testing is more often used for plastics and other softer materials. In Izod testing, the notched specimen is positioned vertically instead .Charpy impact testing was initially adopted for testing metals and then used in many early impact studies on FRP composites. The energy absorption and dissipation during the impact event as well as the failure mode can be tested. The specimen is usually in the form of a thick beam with or without a notch and is supported freely at two ends, as shown in Fig. 3 (a).

Basic principle and practical procedure of the Charpy impact test - Testing machine, test specimen - Basic principle, impact energy measurement - Temperat.Pendulum impact testing machine HIT750P - Charpy and tensile impact tests on metals. By playing this video, you agree to the use of cookies as well as to the transfer of data to YouTube in the USA. A decade before an iceberg shattered the hull plates of the Titanic and half a century before a plague of brittle fractures started sinking Liberty ships during World War II, scientists in the United States and France had devised a novel, and strikingly simple, method for measuring the way metal reacts to impact.. Today, that method, with some upgrades and .

This page introduces the Charpy impact test principle and methods; as well as evaluation methods, test piece standards, differences from the Izod impact strength test, and methods for measurement of the fracture surface. The 3D Solutions Library operated by KEYENCE introduces examples of shape measurement problems and the latest solutions for various industries, .Charpy to ISO 179-1 is the preferred test method on plastics within the standard for single-point data ISO 10350-1. The test is ideally performed on unnotched specimens with edgewise impact (1eU). Should the specimen not break during the test, any subsequent tests are performed with notched specimens. A Charpy impact testing apparatus, a device with a pendulum with various locking points at specified heights and a fixture to hold the test specimen, is used to determine Charpy impact strength. . However, it can also be used for metals. Like the Charpy test, the Izod test is used to determine a material’s toughness and its ductile-to . When testing metals, the indentation hardness correlates linearly with the tensile strength of the material. . Impact Testing – Charpy and Izod Tests. The impact testing method is pivotal for determining a material’s ductile-to-brittle transition temperature and its ability to resist deformation due to impact loads. These characteristics .

Impact test. Measures the ability of a material to absorb a sudden application of a load without breaking. The Charpy test is a commonly used impact test. Lateral expansion. The lateral change in dimension of a Charpy impact specimen due to fracture. The dimension measured is the width opposite the v-notch (see Fig. 1-3).

speed test between wifi and hard wire

History of the Charpy impact test. The history of Charpy V-notch impact testing dates back to the early 1900s when French engineer Georges Charpy developed a standardized method for testing the impact toughness .

In addition to the high energy impact models, Tinius Olsen manufactures a range of low energy pendulum impact testers that can also be easily changed from a Charpy to an Izod configuration. These testers come in a couple of .Torontech’s TTPIT Series of Impact Testers for Metallic Notched Bars are one of its kind of state of art Charpy Impact Testers for Metals build of integrated mainframe and base design, symmetric pillars, and beam supported pendulum shaft, with the features of high stability, good rigidity, simple and reliable structure, and high machining precision.

what is charpy impact test

Charpy Impact testing is used in studying material toughness and most importantly it indicates a material ability to absorb energy and plastically deform without fracturing. In this study, three stainless steel specimens at different temperature -78°C, 80°C and 7°C respectively were utilized. Test criteria for Charpy V-notch impact testing usually involve (i) a minimum impact energy value, (ii) shear appearance of fractured test bars expressed in percent, and (iii) lateral expansion. For steels, the minimum acceptable values generally specified for these three evaluation methods are 20 J, 50 % shear, and 1.3 mm respectively. The Charpy impact test is one of the most widely used techniques for evaluating the impact toughness of metallic materials. This test is based on measuring the energy absorbed by a material during fracture caused by a sudden impact, simulating real stress conditions that could cause a metal component to fracture.

Class J - Charpy and Izod Automatic Impact Testing System - 1J - 50J. Class J is widely used for lzod and Charpy impact test on softer metals, plastics and rubber specimens. Equipped with tensile impact pendulum and fixtures, it can carry on tests on plastic film and sheet.The three most popular types of tests for a single impact are Charpy V, Izod and tensile impact. These three tests determine essentially the same characteristics of the material, but differ in the orientation of the test specimen, which causes the specimen to strain in different directions and involves a known weight released from a known .The Instron MPX motorized pendulum impact test system with the new Bluehill Impact software is the preferred system for metals impact testing to Charpy and Izod standards. Available in capacities ranging from 300 to 900 Joules, the MPX is efficient and easy to operate, making it suitable for high volume testing. Charpy impact testing (also known as the Charpy v-notch test) is a high strain rate testing standard that determines the amount of energy absorbed by a material during a fault (Kim et al., 2015).

Charpy testing is a method for determining the relative impact strength of metals. It is also known as the Charpy V notch test. This testing method was developed in the 1940s by S.B. Russell and G. Charpy. 1.1 These test methods describe notched-bar impact testing of metallic materials by the Charpy (simple-beam) test and the Izod (cantilever-beam) test. They give the requirements for: test specimens, test procedures, test reports, test machines (see Annex A1) verifying Charpy impact machines (see Annex A2), optional test specimen configurations .

charpy impact tester for sale

charpy impact test sample

Bom dia, meu amigo, o sol já se acordou. A alma se renova, .

charpy impact tester for metals|what is charpy impact test